Fim

A JdC desenvolveu uma gama completa de Postos de Transformação (PT) específicos para Parques Solares Fotovoltaicos.

Com potências desde 500kVA a 9000kVA, estes Postos de transformação destinam-se a transformar a energia gerada pelos inversores fotovoltaicos em Baixa Tensão (400 a 800V), para o nível de Média Tensão (10 a 30kV) que permita a interligação à rede elétrica.

Podem ser construídos incluindo os inversores no próprio PT (inversores centralizados), ou incluir o quadro para interligação a inversores descentralizados. Para parques de menor dimensão, o PT pode incluir o SCADA de parque e a função PPC, permitindo assim uma solução “all in one”.

A JdC projeta e fabrica Postos de Transformação em quatro tecnologias construtivas:

A solução “Base Betão” utiliza uma base em betão que funciona como suporte para instalação dos equipamentos que constituem o Posto de Transformação: os equipamentos de média tensão, o transformador Média/Baixa Tensão, e os quadros de baixa tensão para comando, proteção e interligação de inversores.

Esta base funciona ainda como laje de assentamento do Posto de Transformação no solo, e como bacia de retenção do óleo do transformador.

Os quadros de Média e Baixa Tensão podem ser do tipo “outdoor”, ou “indoor” sendo neste último caso o isolamento face ao ambiente envolvente conferido por paineis metálicos tipo “painel sandwich”.

Para parques pequenos (tipo UPP – Unidade de Pequena Produção der 1MW), a JdC produz uma solução “all in one” que inclui o PC de SCADA do Parque instalado no compartimento de baixa tensão do PT.

A solução “Base Betão” utiliza uma base em betão que funciona como suporte para instalação dos equipamentos que constituem o Posto de Transformação: os equipamentos de média tensão, o transformador Média/Baixa Tensão, e os quadros de baixa tensão para comando, proteção e interligação de inversores.

Esta base funciona ainda como laje de assentamento do Posto de Transformação no solo, e como bacia de retenção do óleo do transformador.

Os quadros de Média e Baixa Tensão podem ser do tipo “outdoor”, ou “indoor” sendo neste último caso o isolamento face ao ambiente envolvente conferido por paineis metálicos tipo “painel sandwich”.

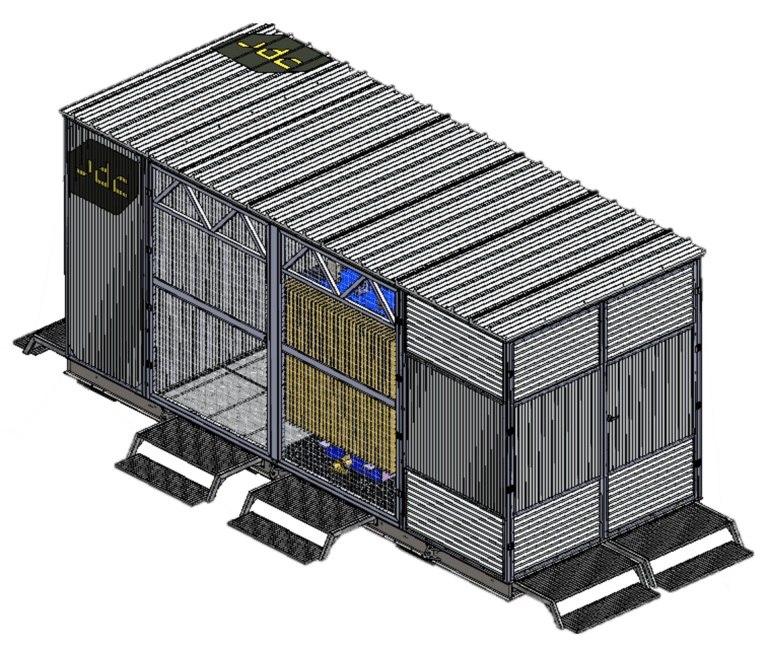

A solução “Skid indoor” assenta numa estrutura metálica tipo Skid, na qual são montados os equipamentos de média tensão, o transformador Média/Baixa Tensão, e os quadros de baixa tensão para comando, protecção e interligação de inversores.

Os quadros elétricos são de exploração “indoor”, sendo o isolamento face ao ambiente exterior conferido por painéis metálicos estruturais com isolamento polimérico (painéis sandwich).

Com dimensões de um contentor metálico, podem ser facilmente transportados.

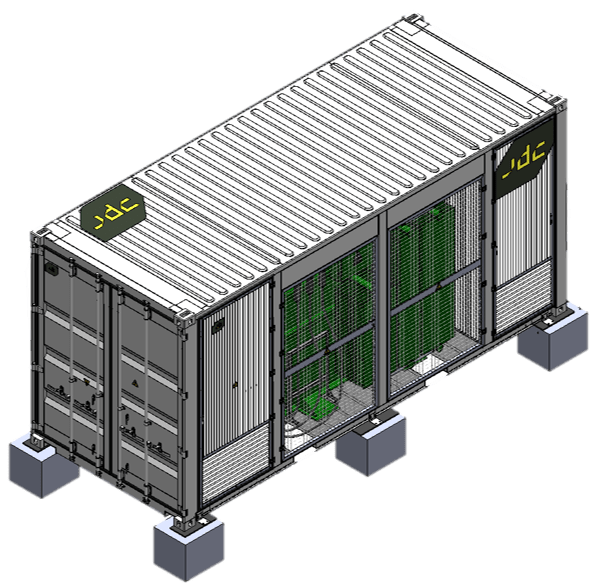

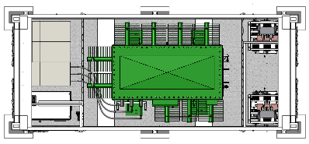

A solução “Contentor Metálico” utiliza um contentor de 20” para albergar os vários equipamentos que constituem o Posto de Transformação:

A sua dimensão e peso permitem que sejam facilmente transportados.

A solução “Contentor Metálico” utiliza um contentor de 20” para albergar os vários equipamentos que constituem o Posto de Transformação:

os equipamentos de média tensão, o transformador Média/Baixa Tensão, e os quadros de baixa tensão para comando, proteção e interligação de inversores.

A sua dimensão e peso permitem que sejam facilmente transportados.